YEARS OF EXPERIENCE

Designing, developing, and manufacturing advanced water flow management solutions since 1965, we take pride in over 40M successful installations worldwide.

Digital Solutions

Digital Solutions

Bringing IoT to your water flow system, keeping you updated in real-time with minimal effort.

BERMADIZE solutions let you stay focused on your business.

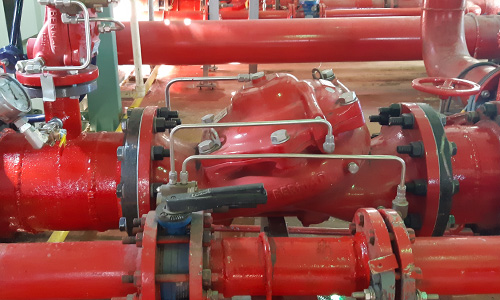

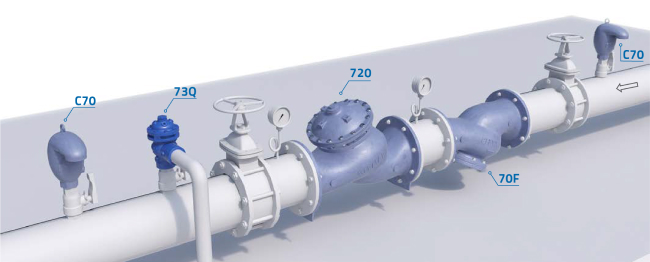

Control The Flow

Explore our catalog by selecting your market and product type to find options for precise water flow and pressure.

Surge & Pressure ReliefPilots & AccessoriesControl & MonitoringElectromagnetic Flow MetersLevel ControlMeteringAir ValvesFlow Control ValvesOn/Off Valves

Pump ControlPilots & AccessoriesPressure Reducing ValvesSurge & Pressure ReliefPressure SustainingFlow Control ValvesAir ValvesElectronic ControlLevel Control