Waterworks

2019

Supplying Jerusalem’s Future

Jerusalem is the capital city of Israel, and it is located in the middle of the country. The city has a remarkable historical and cultural heritage, and holds religious and spiritual significance for people from three religions: Jews, Christians and Muslims. For this reason and more, Jerusalem attracts tourists from all over the world.

In addition to the large number of tourists, Jerusalem also has a population of more than 900,000 people, and in 1994, the yearly drinking water consumption was approximately 60M cubic meters; 2,120 cubic feet. In order to meet the future demand of a rapidly growing population, as well as overcome the challenges posed by an ageing infrastructure, Mekorot (the Israeli national water company) decided to implement a new pipeline system. The objective was to deliver water from the national aqueduct and deep wells near the coastline to Jerusalem.

Transporting thousands of cubic meters per day from the coastline to the mountains in Jerusalem posed tremendous engineering challenges.

Protecting Mountainous Pipelines

Jerusalem has a mountainous topography that varies between +570 to +850 meters; +1,870 to +2,788 feet above sea level, and transporting thousands of cubic meters per day from the coastline to the mountains in Jerusalem posed tremendous engineering challenges. The system proposed included four stages of pumping stations and reservoirs, with a total length of 42 km; 26 miles. For the steepest pipe section a 1,200 mm; 48” PN40; 580 psi steel pipe was used to connect Heller pumping station at +387 meters; +1,270 feet up to a reservoir at +622 meters; 2,040 feet. The Heller pumping station includes six pumps, each of which delivers 2,200 m3/hr; 9,686 GPM.

Together, these achieve the requirement for a total design flow rate of 10,600 m3/hr; 46,670 GPM. Easy calculation brings high velocity of almost 3 m/s; 9.8 ft/s.

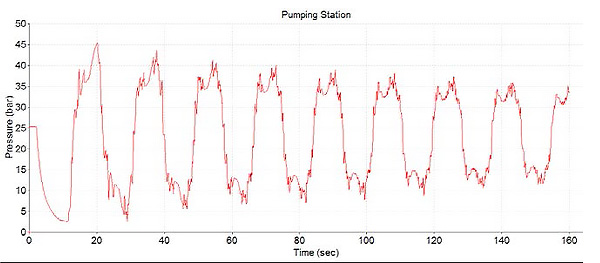

However, this high velocity and the fact that the pump needs to raise the pressure up to 26 bar; 377 psi create enormous potential for severe pressure surges.

Based on our reputation and experience in designing, manufacturing and supplying standout products for water systems, Mekorot turned to BERMAD for a recommendation for a comprehensive surge prevention solution. To provide educated answers, BERMAD engineers preformed a surge analysis using advanced transient flow software.

The results of the simulation were clear: without protection and in a scenario where all of the pumps trip at once, the pressure could reach up to 46 bar; 667 psi, which is way above the maximum pressure allowed in the system.

Graph No. 1: Pressure without protection– pressure rises to 46 bar, which poses a risk to the system

Surge Anticipating Valve Integration

Four units of the BERMAD 835-M DN250 / 10” Surge Anticipating Valves. This full-bore, PN40, piston-actuated valve immediately opens in response to the pressure drop associated with abrupt pump stoppage. The pre-opened valve dissipates the returning high pressure wave and eliminates the surge.

The 835-M valves were installed in parallel to increase the relief flow capacity and reduce the discharge load, thus providing a fully-redundant surge solution. An additional surge analysis was done by BERMAD engineers, which showed that the maximum pressure using the 835-M valves would be 30 bar; 435 psi, which met the client requirement for maximum pressure allowed.

Graph No. 2: Pressure with protection– pressure rises up to 30 bar only

The following video depicts real in-field measurements of water hammer while all pumps trip simultaneously, where the 835-M valves completely eliminate the potential for unsafe pressure rises. These results prove the validity of the analysis initially performed by BERMAD.

The Results

In 1994, four BERMAD 835-M D250 / 10” valves were commissioned and installed. Since then (for 25 years), these valves have provided a reliable and top-quality solution, and Mekorot has implemented additional large-scale, strategic projects using BERMAD products.

As proven in this case study, BERMAD Surge Anticipating Valves guarantee a high-performance surge solution that can be relied on for many years – even in high-pressure systems and tough conditions. Our surge experts offer advanced analysis services for a wide range of projects, as well as excellent assessments of pressure oscillations throughout systems and under various transient scenarios. This means that our surge reports include recommendations based on verified and well-tested hydraulic models, and can be relied on to implement longlasting and reliable solutions.

-

Accurate volume tracking

-

High-pressure tolerance

-

Low-flow detection

-

Maintenance-free design

-

Remote data logging

-

Long-term reliability