Riego

Abastecimiento de agua

2018

Minería / Industrial

Sustainable Irrigation in Almeria

The UN estimates that by 2025, two-thirds of the world will live in water-stressed conditions, with 14% of the global population struggling with absolute water scarcity. Seawater desalination may be the answer to this problem. BERMAD Europe worked together with Acuamed at the Campo de Dalías seawater reverse osmosis desalination plant in Almeria, Spain, on a project that involved using desalinated water for irrigation.

The Campo de Dalías plant is located in one of the most important agricultural areas of Spain. It was approved in 2012 and began operations in October 2015 to remedy the decrease of groundwater levels caused by extensive economic development in the region.

The land and water are highly productive, yielding an average return of approximately 62,000 € per hectare annually.

The Need for Efficient Mixing

Greenhouses in the region produce high quantities of fruits and vegetables and cover over 16,500 hectares of the landscape. The land and water are highly productive, yielding an average return of approximately 62,000 € per hectare annually. However, this region also suffers from a scarcity of groundwater.

At the same time, seawater desalination is an expensive, energy-consuming process, which hinders profitability. For desalination to be feasible, the process has to both produce a large quantity of useable water and be costeffective. To achieve this goal, Acuamed looked for a viable solution that would allow them to mix desalinated water with saline water to achieve a permissible level of saline for the purpose of irrigation.

The EC sensor measures at the outlet of the pipe to indicate the salinity of the water. If the salinity level is below the permissible set point, the salty stream valve opens to increase the inflow. Simultaneously, the valve at the fresh water stream closes, decreasing its inflow.

Once the salinity level rises above the permissible level, the salty stream valve throttle closes to reduce the salty stream inflow while the fresh water valve opens. This process continues on an ongoing basis until the EC sensor indicates the desired saline concentration. Hence, the goal is to maintain this optimal working point between the two valves.

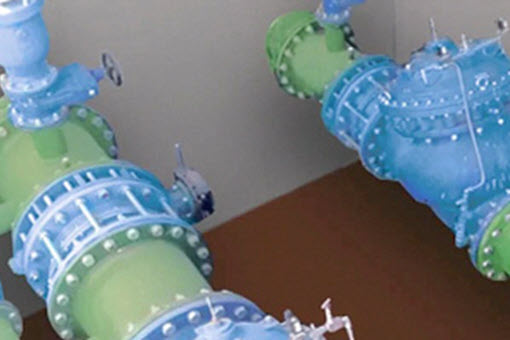

Control Valves for Desalinization and Pressure Relief

The client needed valves to reduce pressure and limit flow in every branch of the system, as the main pipeline divides into smaller pipes to reach the reservoirs. Here, fifteen 772- ES Flow Control and Pressure Reducing Control Valves and ten 730- Pressure Relief Valves were used. These valves belong to BERMAD’s well-known 700 series with a special hydrodynamic design with unobstructed flow path.

Meanwhile, the 730-Pressure Relief Valves were used to relieve excessive line pressure when it exceeds the maximum pre-set, to protect the system from water hammer or abrupt pressure rise. Some of the 730s were used to maintain pump discharge pressure.

To control the mix point and monitor the salinity stability, BERMAD Europe used seven 718-ES Multi Step (Digital) Control Valves. Adding this device automated the control flow and kept the saline levels consistent at all times. The digital control valve is line-pressure driven for independent operation, and can be optimized further through an electronic controller.

To prevent water loss from reservoirs and thus optimize output, BERMAD also placed a burst control valve at the exit of each reservoir. The model in this case was the 790 Burst Control Valve for excessive flow. When this control valve detects an excess flow, it shuts off the flow and stays drip tight until manually reset. It also shuts off in case of pipe burst caused by an earthquake, which is particularly useful as the Almeria region is at risk for earthquakes. The hydraulic pilot is highly sensitive and it is line-pressure driven for independent performance.

Finally, a method was required to control the water level of the reservoirs. BERMAD installed the two 750-80-X Level Control Valves at the inlet pipe of each reservoir. This control valve automatically switches off when the reservoir level reaches the pre-set level. It is also line-pressure driven, and thus operates independently, and as an external installation it is easy to access. Built with a bi-level altitude pilot, this level control valve does not have a float and is cavitation damage resistant. The pilot is extremely sensitive to changes in the water level and always maintains the preset level within a few centimeters.

The Results

For this project, BERMAD Europe used all four mechanisms to create a comprehensive system to combine desalinated and salty water from two or more sources. In addition, all the hydraulic valves were designed with the option for remote control from the customer’s control center.

The BERMAD Europe team supported Acuamed throughout all stages of the project, including solution design, valve supply, commissioning, implementation and after-sale support.

The combination of four different control valve types provided the Campo de Dalías plant with the option of maximizing the applications of desalinated water and secondary water source. By using BERMAD’s control valves, this plant now has the production capacity to provide 7.5 hm3 of desalinated water per year for irrigation.

-

Accurate volume tracking

-

High-pressure tolerance

-

Low-flow detection

-

Maintenance-free design

-

Remote data logging

-

Long-term reliability