Foam Agents, Foam Equipment types and Foam Control Valves

Foam Agents, Foam Equipment types and Foam Control Valves

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > Blog > Foam-Based Fire Protection: An Overview

There are many ways to put out a fire. Depending on the situation, a fire protection system can be designed to work with various fire suppression agents. Plain water is commonly used because it is easily available and effective in many cases. However, water is not always the best choice. Other options include inert gases, dry or wet chemical agents, and different types of fire suppressing foam. In this post, we will discuss foam applications.

Appropriate design and maintenance of a foam-based fire protection system requires an understanding of how and why foam is used. Let’s first take a look at foam applications in fire protection.

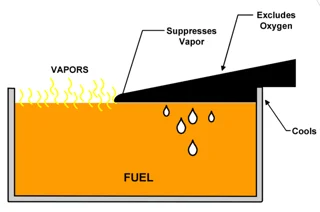

Foam is typically the fire suppression agent of choice in situations where combustible or flammable liquid is stored in tanks or bulk storage facilities. It is especially effective when the flammable liquid has a surface where the foam can be applied. Unlike water, which is heavier than most flammable liquids and will sink ineffectively to the bottom, fire suppressing foam is lighter and will rise to the top. There, it creates a blanket on the surface, reducing vapor formation, preventing oxygen from reaching the combustible liquid and effectively smothering the potential fire.

High expansion foam can also be used to extinguish a fire in a contained space. When used in a railway tunnel, aircraft hangar or other defined space, foam is effective at quickly filling an area and smothering the flames.

Finally, foam also has a cooling effect like water as the foam solution consists mostly of water (~ 97%).

Before we explore these concepts in greater depth, let’s consider when fire protection foam is not appropriate.

Foam is not recommended in the following scenarios:

Chemically, there are two main types of fire protection foam: polar and non-polar. These correspond to two major types of combustible liquid. It is important to use the correct type of foam for the type of liquid present.

Most fire protection equipment designed for use with water can be used for either type of foam. However, the designer and maintenance personnel should be aware of the properties of each specific foam concentrate/solution and select the appropriate equipment settings for each.

Another way to categorize fire protection foam is by rate of expansion. Foam is produced by mixing foam concentrate with water to create a foam solution. This solution then passes through a discharge device (such as a nozzle) which introduces air into the mixture and greatly increases the volume of the finished foam.

Low-expansion foam describes foam that expands in volume 2-20 times from water density to finished foam. This is typically used where the object is to create a fire-suppressing film on the surface of a flammable liquid.

Medium (20-200x expansion) and high expansion foams (200-1000x expansion) are typically used to quickly fill a large volume of confined space, such as a basement, mine tunnel, or aircraft hangar.

Each type of foam and expansion rate calls for different equipment and/or different settings on the equipment. Designers and maintenance personnel should check with foam and equipment manufacturers to ensure proper use and compatibility.

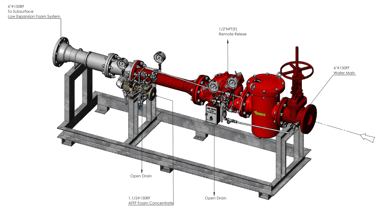

Foam solutions consist of 1-6% foam concentrate, and the rest water. In a typical foam-based fire protection system, the foam concentrate is stored in a storage tank. The exact proportion of foam to water depends on the type of foam used. Achieving the correct proportion requires a special piece of equipment called a proportioner, which feeds the correct amount of concentrate into the water line.

There are two main types of proportioners: pressurized and atmospheric. Each proportioner type is designed to be effective at a particular percentage of concentrate.

Pressurized proportioner: In this system, the foam concentrate is pushed through the system by means of pressure. This can be accomplished with a pump or with a pressurized bladder

tank. The latter is a water tank that contains a bladder within which the foam concentrate is stored. The concentrate bladder is pressurized from the outside by the water pressure surrounding it. The pump or pressurized bladder forces the concentrate into the proportioner.

Atmospheric proportioner: This type of proportioner uses atmospheric pressure to suck the foam concentrate through the system like a straw in a glass of water. The water moves through a small orifice, creating a Venturi effect which, creates sufficient suction to pull the concentrate from a small atmospheric storage container into the solution. This type of proportioner is designed to proportion 3-6% of foam concentrate to water.

Deluge Valves are a critical component of any foam-based fire protection system. Typically, there will be a Deluge valve on the water piping. In addition to the main deluge valve there is also a foam valve that provides the foam concentrate to the proportioner. Most fire protection deluge valves may be used with either water, foam solution or foam concentrate.

Pressure control valves are also a critical component to consider. Controlled pressure enables more accurate proportioning and application rates. In a foam system, it’s best to have pressure control on both the water and the foam sides of the system.

Once the foam concentrate has been proportioned into the water it’s necessary to use a discharge device to whip it up into foam. Different types of discharge devices are available for different types of foam. Low expansion foam can be used with standard nozzles. Medium and high expansion foams require special equipment such as a foam generator capable of mixing a great volume of air into the solution. An aspirating system for this type of foam can increase the volume of solution by 200-1000 percent.

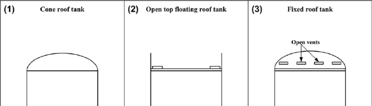

Liquid fuel storage tanks are a prime candidate for fire protection because the large volumes of flammable liquids involved create high hazard potential. When designing such a system it is important to take the type of storage tank into account. There are two main types of storage tank: those with a fixed roof vs. those with a floating roof. Each calls for a different type of foam-based fire protection system.

A fixed roof storage tank is a standard tank that contains a volume of liquid. As the liquid exits the tank, a volume of vapor-filled space opens up above it. Protecting the exterior roof of such a tank would be ineffective because of the potential for the vapors inside to ignite and explode, thus damaging or destroying any fire protection equipment present on the roof. Instead, a subsurface fire protection system is typical. In such a system, the foam solution enters the tank at the bottom. After being released through the flammable liquid by means of special nozzles, the foam floats on top of the liquid, forming a protective blanket on the surface.

In a floating roof storage tank, the roof of the tank floats freely on the liquid surface. As liquid is drawn out of the tank, the roof descends to eliminate empty space in the tank. This type of storage tank is designed to minimize or eliminate the presence of vapor inside the tank. This helps to reduce the evaporation rate of the liquid. It also reduces the possibility of fire, because it’s the vapor that burns, not the liquid itself. However, the perimeter of the roof features a flexible seal that permits the roof to float. Vapor can escape around that seal, creating a potential fire hazard.

In this case a subsurface fire protection system won’t help because the low roof prevents any blanket of foam from forming at the liquid’s surface. Instead, the top of the roof is protected with special equipment called a foam pool.

BERMAD’s fire protection division is fully committed to excellence in design and customer service. For assistance with your foam-based fire protection system design and application needs, contact a BERMAD representative in your region.

We got your email. Now, let’s make it personal...