When to use air valves and what are their benefits and types?

What are the benefits and function of an air valve?…

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > Blog > Save Energy and Costs with BERMAD’s 100 Series Double-Chambered Hydraulically “Transparent” Polymeric Valves

By

The BERMAD 100 series valves really do have it all.

Sound too good to be true? Let’s delve into the unique features and benefits of these valves so that by the end of this blog post, you’ll be convinced that you really can have it all with BERMAD 100 series double-chamber valves.

With BERMAD’s 100 Series hydraulically “transparent” double-chamber valves, black is the new green

Why black?

BERMAD’s 100 Series double-chamber valves are made out of reinforced black polymer. Designed to offer a high level of mechanical strength and flexibility, they can operate in a wide variety of pressure conditions. Cost-effective, easy to install, and easy to maintain due to their light weight, BERMAD’s 100 Series double-chamber valves eliminate corrosion and offer a high level of resistance to chemicals and cavitation.

Why green?

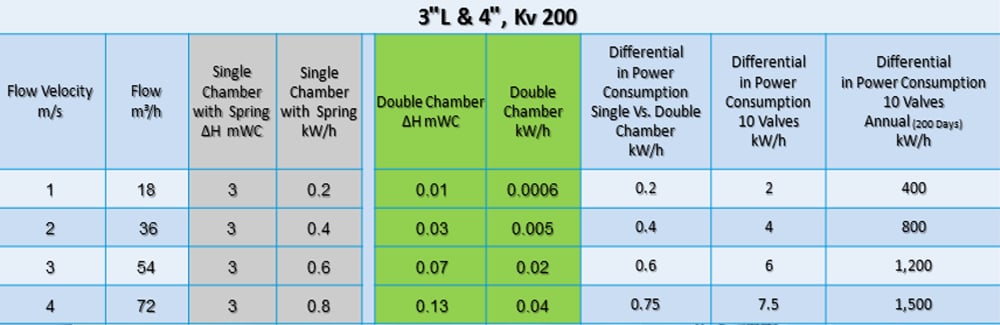

BERMAD 100 Series valves were designed to reduce energy consumption and pressure loss, and lower the carbon footprint of irrigation systems. They have a “Y pattern body” and look-through design, so that once open, they resemble a pipe and create near-zero additional head loss in the system. When these valves are further equipped with a double-chamber actuator, they become hydraulically “transparent”, minimizing head loss even more. This leads to a reduction in the overall energy requirements of irrigation systems.

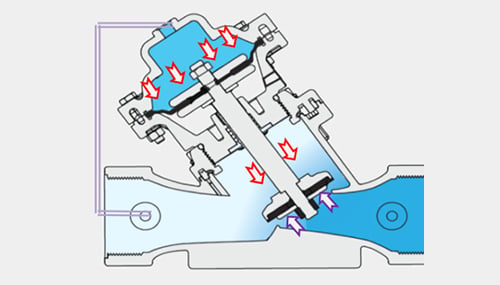

Fast and powerful, smooth non-slam closure without water hammer

In BERMAD’s 100 Series double-chamber valves, the diaphragm is isolated from the downstream. When the valve is opened, the closing and opening forces on the seal disc neutralize each other. To start the closing process, upstream pressure is diverted to the upper control chamber. Since there are no opposing opening forces, the diaphragm assembly and shaft move the seal disc quickly, in a linear direction and with high force, towards the seat.

When the valve is almost closed, downstream pressure starts to diminish, the balance of forces on the seal disc changes, and the upstream pressure causes the closing process to slow down for smooth and soft closure. This built-in feature is essential to irrigation systems as it provides quick and accurate valve reaction to changing hydraulic conditions, while protecting systems from damaging scenarios such as water hammer due to valve closure.

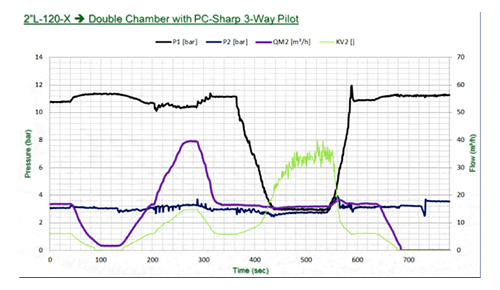

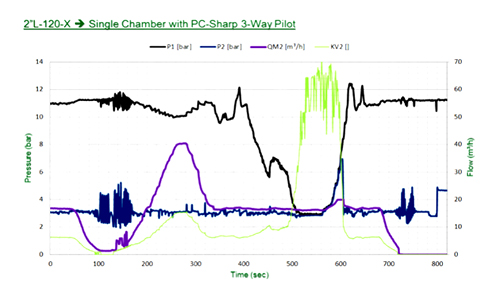

Immediate response to enter modulating mode

In regulating valves, an immediate response and adjustment of the valve opening rate is required when the flow or pressure conditions change. For example, in the case of low-pressure and high-demand in the network, a pressure-reducing valve with a three-way pilot completely vents the control chamber, enabling the valve to open fully. In cases of significant demand drops, the valve should throttle close to prevent a downstream pressure rise. Double-chamber valves, as a result of the closing and opening forces on the seal disc that neutralize each other, react immediately and minimize pressure rise.

Accurate and stable modulating even in very low flow rates

When a valve is in modulating mode, its seal disc is very near to its seat. In very low flow rates, this distance may be only fractions of millimeters. The area near the seat is exposed to high velocities and turbulences; and in single-chamber valves, this affects the seal disc and diaphragm and changes the opening forces rapidly to create instability. In double-chamber valves, the diaphragm is isolated from the line flow, so no opening forces are applied on it. In addition, the opening forces on the seal disc are partially neutralized by the closing forces. The effective diaphragm area is reduced as most of the diaphragm leans over the separating partition; and this restricts the closing forces, restraining valve closing speed even more. The result is stable and accurate modulating, even at very low flow rates.

Double-chamber valve with 3-way PC-sharp pilot

Single-chamber valve with 3-way PC-sharp pilot

Pilot-less proportional pressure reducing: No pilot, filter, or restriction

In a double-chamber valve, connecting a control tube from the valve downstream to it’s upper control chamber creates a proportional pressure-reducing mechanism that reduces any level of upstream pressure to a lower downstream pressure at a constant ratio.

This is done without the need for a pilot, control-water filter, needle valves, or restrictions. Only a “full-bore” control tube is required to achieve an immediate response, absolute stability, and very high reliability.

Watch this video for more detailed information about the benefits of BERMAD 100 Series valves for irrigation.

You really can have it all – save energy & costs, protect your water systems, and improve irrigation efficiency and uniformity

BERMAD 100 Seriesdouble-chamber valves are made from composite polymeric material for enhanced mechanical strength and flexibility and offer a number of features that are unique in the market. These include hydraulic “transparency” for near zero head loss, fast and powerful, smooth non-slam closure, immediate response in varying conditions, precise and stable control at all flow rates, and pilot-less proportional PRV.

These features enable you to save energy and costs, reduce environmental footprint, protect irrigation water systems, and enhance irrigation efficiency and uniformity. So you really can have it all!

We got your email. Now, let’s make it personal...