When to use air valves and what are their benefits and types?

What are the benefits and function of an air valve?…

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > Blog > Self-Actuating Valves vs. Control Valves

When selecting a valve for a particular application, operators have a number of different design options to choose from. Most of which fall into one of two categories: self-actuating and manual/control.

Each type provides advantages and disadvantages that will make it more or less suitable given the demands of the fire protection/suppression system and the facility where it will be installed. Understanding how they function, as well as their differences, is critical to making the proper selection.

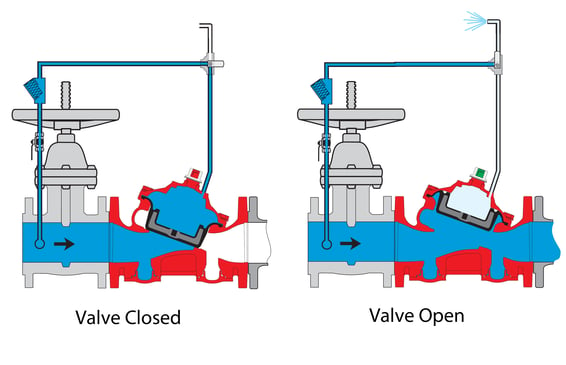

Self-actuating valves can be triggered by a pneumatic, hydraulic or an electrical signal, and need no external power supply to operate, using the process fluid pressure to power the valve to open, close or modulate. Typically, a self-actuated valve uses a line pressurized and spring loaded diaphragm in order to achieve a force balance or bias against the process fluid.

The valve is triggered to increase or decrease flow or pressure in response to any pressure change on the diaphragm, moving it and thereby changing the flow passage area.

In hydraulic lines, when more flow or pressure is needed, fluid pressure on the valve’s diaphragm decreases, thereby reducing the force on the diaphragm and spring allowing the plug, or closure to move to open and increase the flow area, and visa versa when less flow or pressure is needed. This results in a process-powered system whereby flow/pressure increases and decreases on demand.

Self-actuated valves react more directly and immediately to any change in pressure on the diaphragm, allowing them to respond more rapidly than manual or control valves. They are also much easier to maintain and require no packing box, greatly reducing the possibility of volatile emissions potential. Self-actuated valves, however, are limited to somewhat smaller sizes in comparison to control valves.

Communication occurs through a control loop to the host control system (usually a distributed control system – DCS). The DCS will interpret the request by identifying the valve’s current position and gauging how it should deviate from the predetermined set-point value. An electronic signal is then transmitted to the DCS controller, which in turn signals the valve positioner, producing a pneumatic, hydraulic or an electric action to reposition the valve.

Control valves require an external power source to respond to a trigger to alter the flow passage. Typically, this trigger comes from sensors, which are designed to send a signal to the valve under certain environmental conditions. The valves can also be triggered manually by an operator. Sensors or operators enact change in the valves throttling position according to a specific temperature, pressure or flow rate.

Control valves can operate without system line pressure. This is in contrast to self actuated valves that rely on system line pressure for operation.

Exposure to process fluid can limit self-actuating valves’ use in certain corrosive applications. Control valves, on the other hand, are easier to protect from corrosion as the diaphragm is usually separated from the process fluid.

Ultimately, the optimal choice of valve will be dictated by the unique needs of the application for which it is intended.

Be it self-actuated or manually controlled, it is fundamental to ensure that these vital components be of the highest manufacturing quality. This is particularly the case in fire suppression systems where valve reliability and performance are critical to overall safety.

In these applications, market-leading products such as the FP 400Y-1D Manually Operated Monitor / Deluge Valve can serve as an ideal choice. The valve features a highly unique one-piece molded elastomeric design, which minimizes maintenance requirements. It is also inline serviceable and includes an obstacle-free full bore, providing uncompromised reliability in even the harshest of operating environments.

We got your email. Now, let’s make it personal...