Waterworks

2019

Australia

Reliable Flow Under Pressure

Australia is a thirsty nation. As a country, it is among the world’s highest consumers of water. Yet, it is also one of the driest inhabited countries on Earth and vulnerable to droughts, which can lead to acute water shortages. Most of the municipal water supplies comes from surface water, which in the face of climate change, underscores the need to protect and maintain the water supply systems upon which the public depends.

Cavitation, which can damage delivery networks, is a given in all water supply systems. However, it is a particular concern in Australia where water supplies are already limited. Cavitation occurs because of the pressure needed to move water through the system. When water pressure in the valves and pipes falls to blow the vapour point, it causes a process called flashing in which bubbles form in the moving water. Then, when the pressure rises again, the bubbles collapse causing cavitation – millions of tiny shockwaves that pit and scour the inside of the valves and pipes. In systems with inadequate pressure controls, cavitation can lead to significant damage, including pipe bursts, and ultimately a pipe burst if pressure is not properly controlled.

A Risky New Pipeline

Cavitation was a top concern for one municipal water authority in Southern Australia as it sought to develop an alternative source of water to meet the demands of a growing population. The utility was already serving more than a million people and needed a new pipeline to serve as a backup. With such a large system, maintaining the proper pressure to ensure the delivery of water throughout the entire network was difficult.

To improve its ability to provide water throughout one of its reticulation areas, the utility had installed a large transfer pipeline and was tapping off this pipeline as a secondary source of water. However, the variable inlet pressure in the new pipeline was producing occasional high transient pressure waves leading to concerns that the high pressure surges would damage the pipes in the network.

This was a very real concern. In a system with such widely varying pressure, the cavitation it can cause would made the addition of a new pipeline risky business and the selection of a valve to control it of paramount importance. So, the utility turned to BERMAD for a solution – a valve that would work reliably without cavitation to ensure the safety and stability of its pipeline.

Cavitation-Resistant Pressure Control Valve

BERMAD understood the critical nature of the situation. With more than a million people relying on the utility for their water supplies, valve failure would could be catastrophic to the downstream reticulation network.

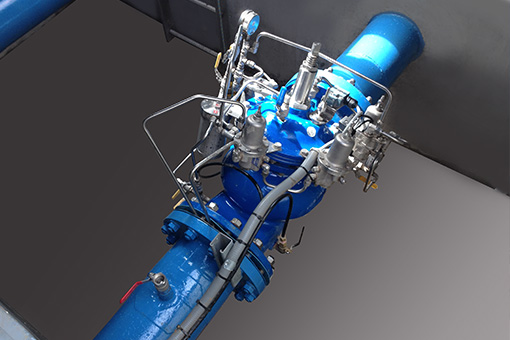

BERMAD worked with the utility and its design engineers to install a 700 SIGMA Series valve, which is highly resistant to cavitation and explored additional safeguards available to ensure the valve would protect the pipeline and function well in the widely varying pressure conditions they faced. These safeguards included:

- Installing dual large cartridge filters to prevent the blockage of the components on the valve

- A mechanical limiting flow stem in the middle of the valve that would limit the flow in the event of valve failure, thereby limiting any damage to the network

- A hydraulic “overpressure guard system” designed to shut down quickly in the event of a significant rise in pressure.

To protect the valve itself, BERMAD recommended a model that would provide an elevated seat and wide body to ensure the effects of cavitation would not impact the valve body regardless of the flow conditions. To support the recommendation, BERMAD provided the utility with a full sizing analysis report, which proved that its valve design would not only provide better pressure control but also withstand significant cavitational forces.

BERMAD’s New 700 SIGMA Valves Offer Superior Cavitation Resistance

BERMAD’s 700 SIGMA valves are hydraulically operated, pressure reducing control valves that reduce higher upstream pressure to reduce constant downstream pressure, regardless of fluctuating demand or variations in upstream pressure. Here are some of the key features these robust valves offer:

- A double chamber configuration using a three-way control, which makes them extremely responsive regardless of operating conditions and allows for full opening without the risk of hydraulic lock out

- Extremely accurate pressure reduction over high differential pressure regardless of the inlet pressure range

- A hydraulic over pressure guard system that immediately closes the valve to regulate flow when the downstream pressure rises more than 10% of the set point

- An integrated solenoid shut-down from telemetry to provide additional assurances in high pressure conditions that exceed the setting of the overpressure guard system

- A hydraulic flow control function to limit the flow to avoid excessive cavitation across the valve under high flow and differential pressure conditions

- An indicating rod with a micro-switch to send alarms to operators to shut down the network in the event that a fault occurs resulting in a full opening of the valve

- Dual large-cartridge duty and standby filters fitted with internal stagnation tubes to minimize the rare possibility of solids blocking needle valves and pilot controls

In addition, while the possibility of diaphragm failure is extremely rare, these valves also feature a mechanical flow stem designed to limit the valve travel and reduce the choked flow capability of the valve to minimize any risk to the downstream network.

The Results

After installing and commissioning the first SIGMA 700 valve for the utility in Australia, BERMAD conducted thorough testing offline to prove that the valve would operate and run under the varying pressure conditions protecting the system’s pipeline without experiencing cavitation. The valve passed all tests with flying colours, proving that it would provide the utility with the network protection it needed along with flawless performance and reliability. The utility has now installed a total of four SIGMA 700 valves, all of which are helping the system more effectively manage the pressure changes.

For this large utility, finding a solution to its pressure management issues that would also protect its system against the potentially devastating effects of cavitation was about trust and performance, which it found in working with BERMAD. With more than 50 years of engineering expertise and experience developing, designing, and manufacturing stateof-the-art hydraulic control valves, including valves for high-risk applications such as this, BERMAD was able to help the utility meet the growing demand for water in the communities it serves with greater confidence in the safety and integrity of its entire network.

-

Accurate volume tracking

-

High-pressure tolerance

-

Low-flow detection

-

Maintenance-free design

-

Remote data logging

-

Long-term reliability