Irrigation

2025

Italy

Mining / Industrial

Injection Monitoring in Geotechnics

Dai Prà, a long-established Italian company specializing in geotechnics and environmental remediation, developed a proprietary line of injection and mixing systems for soil consolidation and site restoration. As part of their innovative approach, they integrated electromagnetic flow meters to ensure accurate and compliant delivery of injection materials under challenging operating conditions.

Tackling Complex Injection Demands

Modern geotechnical and remediation projects increasingly require real-time monitoring and precise control of fluid injection data—flow rate, pressure, and volume. Dai Prà’s applications involved high-solid-content mixtures (such as cement and oxidizing fluids) injected at pressures up to 110 bar. Ensuring measurement accuracy despite abrasive mixtures, low flow rates, and challenging site conditions was critical for compliance and performance assurance.

Smart Flow Monitoring Integration

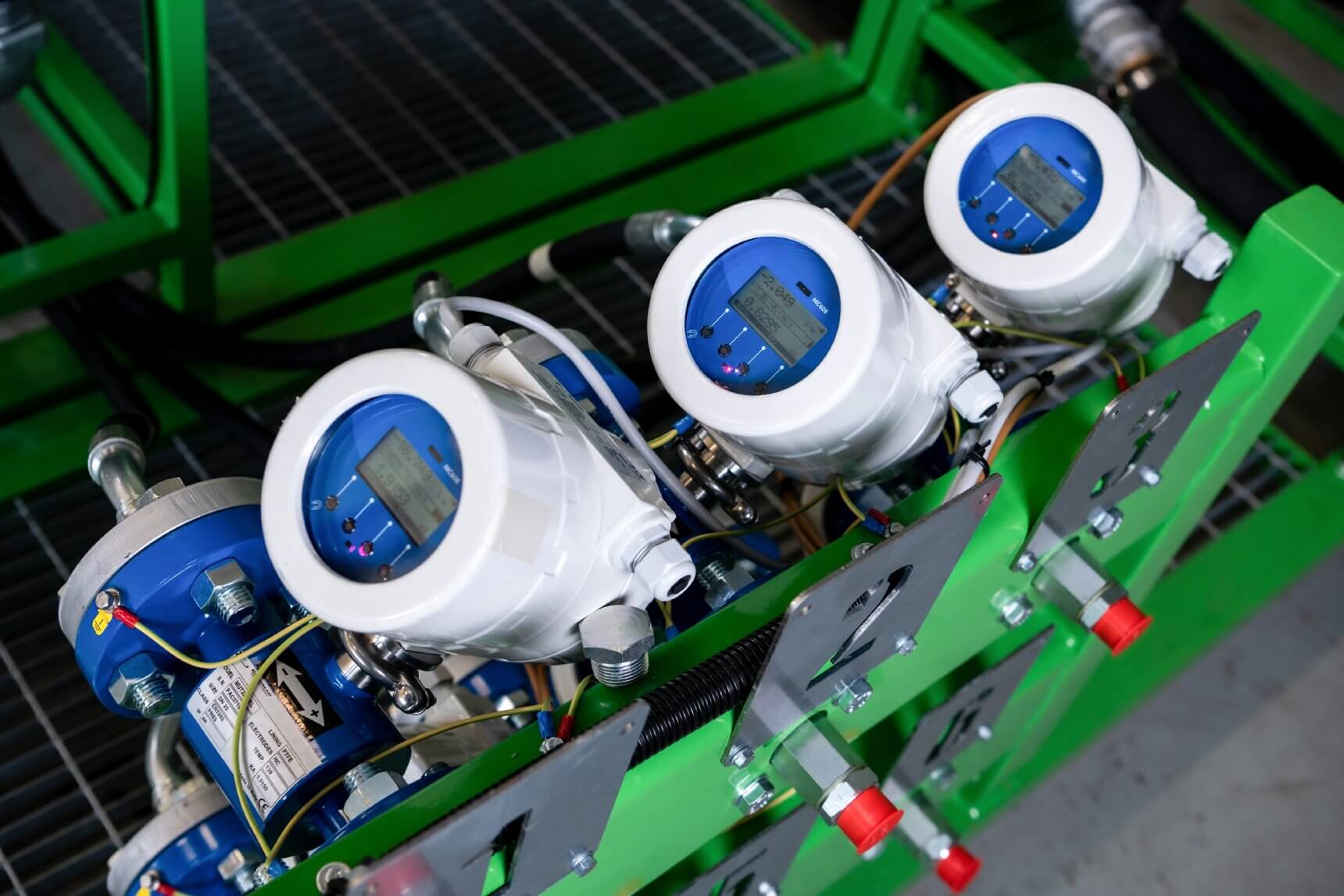

To meet these demands, Dai Prà implemented BERMAD’s MUT2200EL electromagnetic flow meters, chosen for their high accuracy, extended linearity, and durability under extreme conditions. The flow meters were installed in flanged PN64 configurations to handle high-pressure cementitious and chemical mixtures.

The system architecture included:

- Automatic turbomixers producing the injection mixture

- Agitator tanks with level sensors

- Six injectors, each managed by dataloggers and equipped with pneumatic valves

- Inline MUT2200EL meters, integrated with the control and logging system

The MUT2200EL’s ability to detect even very low flow rates without linearization software allowed precise measurement across the entire flow range. Built with a stainless-steel flow tube and electrical insulation, and designed with no moving parts, these meters ensured long-term reliability with minimal maintenance.

-

Accurate volume tracking

-

High-pressure tolerance

-

Low-flow detection

-

Maintenance-free design

-

Remote data logging

-

Long-term reliability

Products in Use

Explore our catalog of advanced water control products, designed to meet real-world demands

and deliver lasting performance.

Related Case Studies

See how our solutions perform in real-world scenarios with in-depth case studies

and hands-on application success stories.