Water Safety Valves for High-Rise Buildings

For reliable high-rise water systems, choose suitable control valves and…

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > How To Guides > How do Strainers Interfere with Pressure Control Valve Performance?

Pressure oscillation is a phenomenon that develops in some water supply systems in high-rise buildings. It can be a nuisance for building occupants as it creates unstable flows in faucets, disturbs the stable mix of hot and cold shower water, and might even damage delicate appliances such as washing machines and dishwashers.

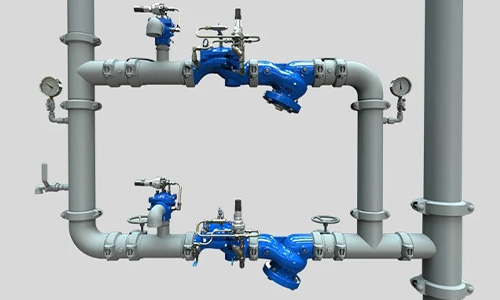

A high-rise building water supply system can include a variety of control components meant to provide stable pressure and prolong the lifespan of the system. These include water hammer solutions for the pumping system, air valves at key positions to allow free water flow, and pressure control valves (PRVs) for proper pressure distribution along the tall building.

But these are not the only control components capable of affecting system pressure. When designing or modifying a water supply system, it is important to keep in mind that virtually any system component—even those that are often overlooked such as strainers—can affect system pressure and potentially contribute to pressure oscillation. Problems related to pressure oscillation on a consumption-site basis such as showers and taps in buildings are often associated with a pressure control valve, since it is usually the only point in the system that has a manometer that allows the verification of this oscillation. However, oscillations shown upstream of pressure reducing valves may actually originate from the pressure control valve gravel trap or strainer.

In order to protect the PRV from debris that may flow in the pipeline and disturb its operation, a pressure reduction station should include a strainer that is installed on the upstream side of the PRV.

The following are some possible causes of excessive pressure loss at the filter site:

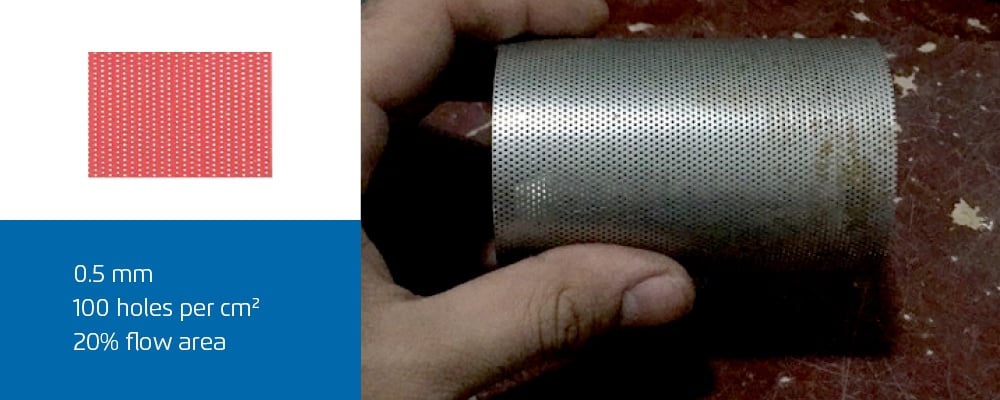

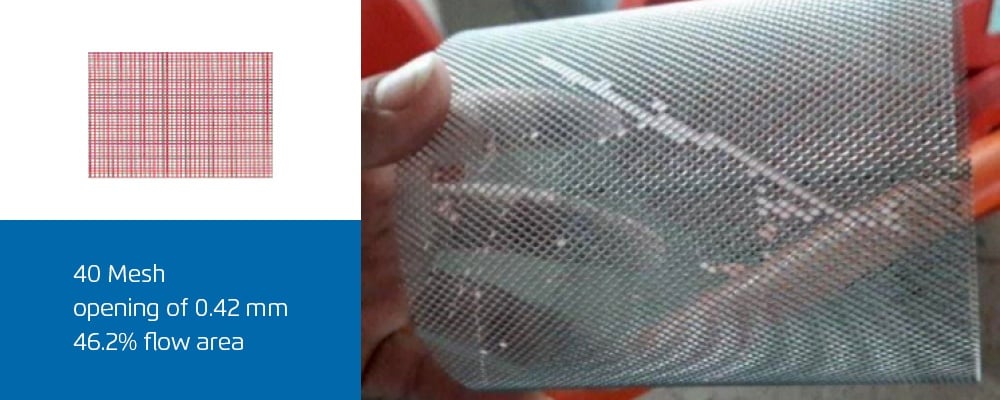

As you can see, the 0.5 mm perforated screen in the image on the top actually has less than half the open area of the 0.42 mm mesh screen in the image on the bottom. This is enough of a difference to significantly affect the likelihood of its clogging and subsequently causing pressure oscillation issues.

2. Lack of filter maintenance

Even an appropriately sized filter can clog if it is not properly maintained. As the photos below demonstrate, it is not uncommon for significant obstructions to be carried through supply pipes and lodge in the filter. Partially or completely clogged filters compromise water flow, which can result in strong pressure oscillations in the system.

Strong pressure oscillations are especially likely to happen when there is an increase in consumption demand. While the pressure control valve itself will have a modulating effect, when the pressure loss is located in the filter, it may compromise the outlet pressure of the valve.Ideally, a Y filter should create a small enough pressure drop to maintain compatibility with the design pressure of the point where it is installed. To avoid excessive pressure loss and subsequent pressure surges in the system, filters should receive regular maintenance. It is a good idea to clean and inspect pressure control valve filters whenever the upper reservoirs go through cleaning or maintenance.

BERMAD provides comprehensive support for engineers and designers of water supply systems. If you would like to know more about how we can help you eliminate pressure oscillation and other unwanted water supply system problems in your next building or construction project, contact us here to get in touch with a BERMAD representative in your region.

For reliable high-rise water systems, choose suitable control valves and…

Benefits of Low Flow Bypass Pressure Reducing Valves in Buildings

Emergency Valves for Pressure Control Systems in High Rise Buildings

We got your email. Now, let’s make it personal...