Water Hammer Solution in Multistorey Building Applications

How to handle water hammer – pressure surges in high-rise…

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > How To Guides > How To Commission and Maintain a Tank Fill Valve

Once a tank fill valve has been selected and installed in accordance with manufacturer instructions — there are several ways to ensure its optimum performance. Michael Jacobsen takes us through the commissioning, maintenance and troubleshooting of hydraulically operated tank fill valves.

When a tank fill valve has been accurately chosen for an application, there is little experience required to commission it. By following the steps below, you will be able to maximise a trouble-free operation without adding to installation time:

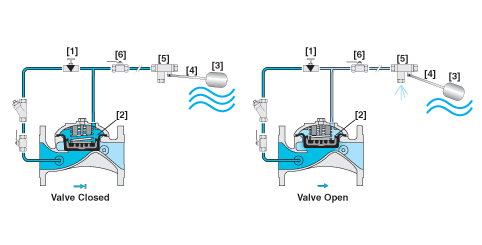

When turning on the water for the first time, the valve should be open. This will allow water to flow through the tank — even if the tank is full. This is because the valve control chamber is not pressurised. It will take a short while for the control chamber to pressurise, and the valve to close if the tank is full.

The valve will remain open if the tank water level is below the shut-off level.

Releasing air from the valve control chamber is also recommended. This can be done by loosening a nut on the tube connection fitting at the highest point.

Water will start to escape after only a turn of the nut — allowing the air to release.

Once the air bubbles stop coming out with the water, the nut can be retightened.

Tank fill valves that are installed in buildings are generally working with clean water. This means that they do not often require regular maintenance. There may be a building code or regulation that stipulates periodical maintenance be conducted, and in these circumstances, maintenance can be made simple and practical. Maintaining tank fill valves usually involves replacing diaphragms after an extended period of operating time.

There are a few circumstances where the common hydraulic tank fill valve is unable to function within an application. Examples of this include:

The valve does not open when the tank level has dropped.

When a valve doesn’t open in response to a drop in the tank water level, it is because something is preventing the valve control chamber from de-pressurising. Settings to check are:

Majority of people experiencing issues with tank fill valves, cite problems with the valve failing to close once full. The most common reason for this problem is a result of debris, particularly stones, being trapped in the valve. This is especially the case for systems that don’t have strainers or stone traps installed. Settings to check are:

If you would like further information or manuals for the tank fill valve, please visit the product page to learn more.

If you are interested in utilising this product in your next project, get in touch with us via our website, or contact your local sales office — we’d love to hear from you.

We got your email. Now, let’s make it personal...