Water Hammer Solution in Multistorey Building Applications

How to handle water hammer – pressure surges in high-rise…

Did You Update BERMAD Connect Already? Check It Out

Update BERMAD Connect Today! Check It Out

BERMAD > Knowledge Center > How To Guides > How To Service a Pressure Reducing Valve

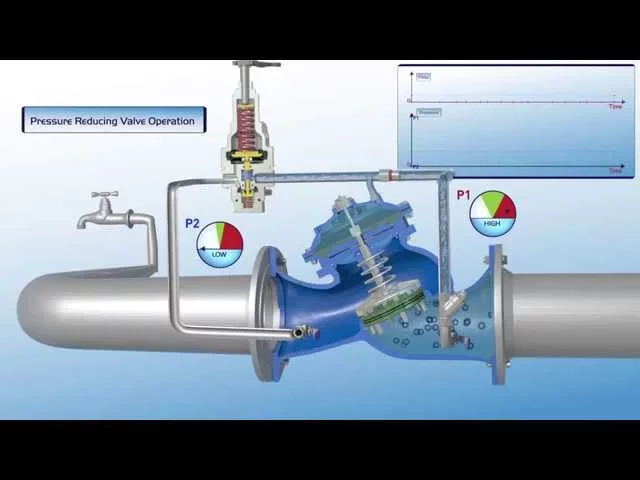

A pressure reducing valve is a hydraulically actuated pressure reduction valve that will automatically modulate using water pressure to maintain a constant downstream pressure regardless of inlet pressure and flow rate.

A pressure reducing valve like the Bermad model 720EN incorporates a series of hydraulic pilots, speed controllers, filters, and other accessories to ensure that the hydraulic valve automatically modulates.

Check out the following video to see the workings of a pressure reducing valve:

When it comes to performing regular maintenance on pressure reducing valves, timing is everything. Like you would service your motor car to prevent failure of components, it’s critical to do preventative maintenance on a pressure reduction valve to ensure reliable and accurate operation.

Maintenance intervals are very much dependant on several different operation conditions. Conditions that will impact the valve performance include:

In best engineering practice, preventative maintenance is recommended for every 6-12 months that the valve is in operation. This involves the basic service of the key components without going into the valve body itself.

Major servicing of the valves should be considered every 6-10 years, which includes internal inspection of the main valve as well as the external components.

A regular service can usually be done quickly without taking the entire valve offline.

To ensure the valve is operating at maximal performance there are four key considerations that are critical to the valve’s operation:

Experience has proven that these four specific components in the PRV are maintained, the reliability of the valve is extremely high.

Learn more about the process of maintaining the model 720EN control valve in the video below:

If the valve has been correctly sized and designed from the start, a major service is where the internals of the valve are inspected. A major service of a pressure reducing valve generally occurs after six years of the valve being in operation.

When a major service is undertaken, the valve is turned offline, and the entire actuator is removed from the valve. The following video shows how to remove the actuator:

The key areas to inspect or replace when the actuator is out is as follows:

To learn how to disassemble the control valve from start to finish, check-out the video below:

Here at Bermad, we’re committed to providing the information you need for products, technology, and operating systems. That’s why we’re committed to ensuring that users of our pressure reducing valves have the best information on the functions of all our products.

If you have any further questions, require additional details, or wish to discuss any technical aspects of the air release valve, you can:

We got your email. Now, let’s make it personal...