Burst Control Valve, Excessive Flow

with Mechanical Flow Stem

790-M

700 Sigma Series

Waterworks

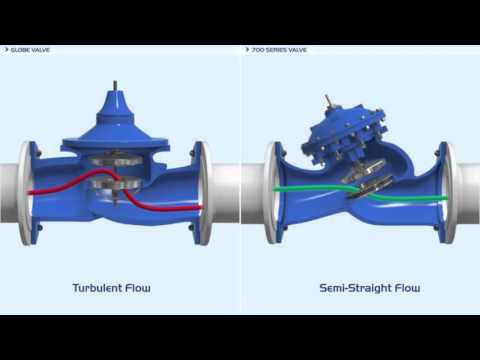

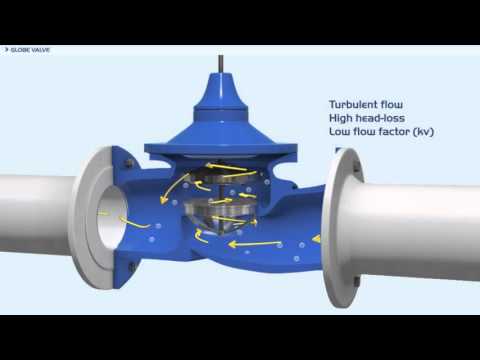

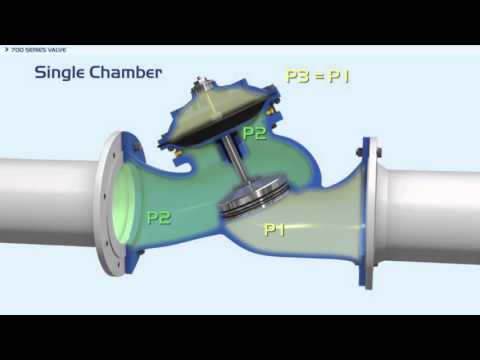

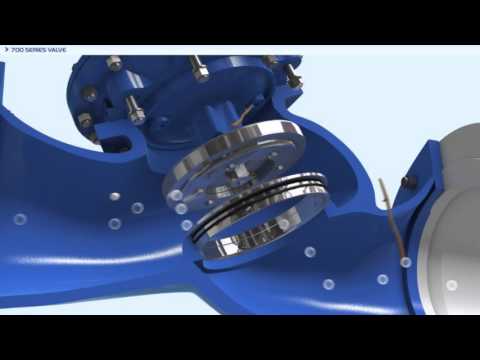

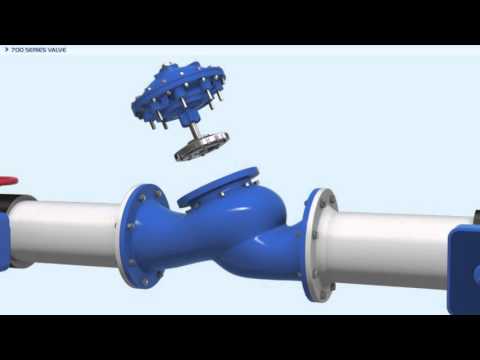

Hydraulically operated, diaphragm actuated, burst control valve that senses flow levels. When it senses flow in excess of settings, it shuts off and locks drip tight until manually reset. As long as flow is lower than settings, the valve remains fully open, minimizing head loss. A flow stem enables limiting valve opening stroke, precisely adjusting the required flow through the valve.

Need more information? Contact us here

- Designed to - Stand up to the toughest conditions

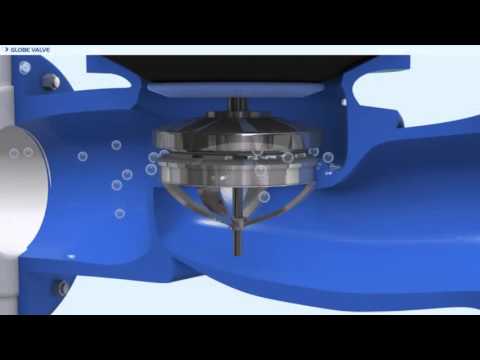

- Excellent anti-cavitation properties

- Wide flow range

- High stability and accuracy

- Drip tight sealing

- Double chamber design

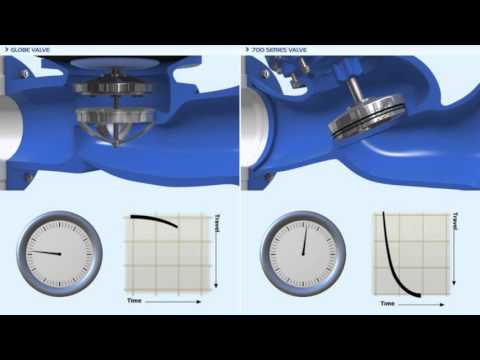

- Moderated valve reaction

- Protected diaphragm

- Optional operation in very low pressure

- Moderated closing curve

- Flexible design - Easy addition of features

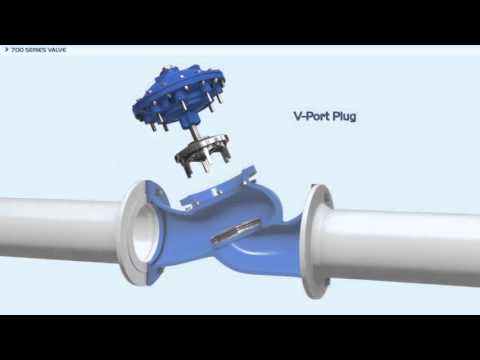

- Obstacle free flow pass

- V-Port throttling plug (optional) - Very stable at low flow

- Compatible with various standards

- High quality materials

- In-line serviceable - Easy maintenance

Typical Applications

- Old or sensitive pipe systems ‑ Prevents flooding and water loss