Who are we?

We are experts in water flow management.

We design, manufacture, optimize and support connected products and

Solutions to enhance and protect water systems

In Waterworks, Irrigation, Buildings and Fire Protection

Who are we?

We are experts in water flow management.

We design, manufacture, optimize and support connected products and

Solutions to enhance and protect water systems

In Waterworks, Irrigation, Buildings and Fire Protection

What is our differentiation?

Standout connected products with a committed professional team

Behind them to ensure added value and greater efficiency.

Global reach with strong local presence and long-term relationships.

What is our differentiation?

Standout connected products with a committed professional team

Behind them to ensure added value and greater efficiency.

Global reach with strong local presence and long-term relationships.

BERMAD in numbers

-

0Subsidiaries

-

0Years

-

0Countries

-

0Install Base

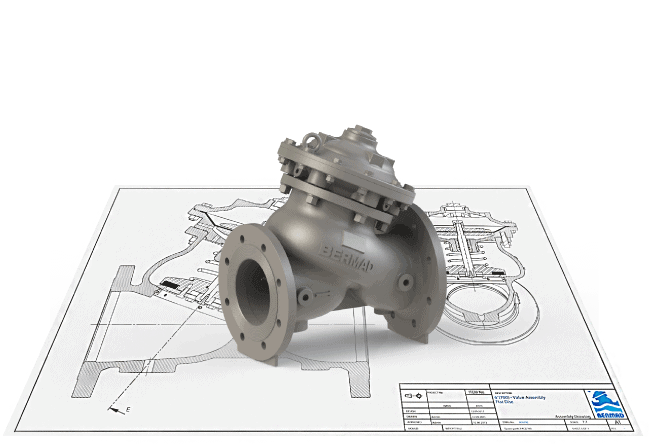

BERMAD - Advanced Technology & Precision Engineering

Compliant with the most stringent international Standards and Approvals, all BERMAD products are designed and developed in-house by the company’s expert R&D teams, and are manufactured in its ISO 9001 certified facilities. Incorporating unique patented technologies and exploiting the benefits of advanced metal & composite materials, BERMAD high quality products have been perfected through years of hands-on experience. As a result, BERMAD’s advanced control valves are deployed throughout critical water and other fluid supply settings, offering proven solutions for a wide variety of applications. Today the company offers the most complete range of multi-purpose and task-specific control valves available on the market.

BERMAD Worldwide

With 14 offices around the globe and a wide network of distributors, click on the segment below to find your nearest representative.

Click for :

IRRIGATION / BUILDINGS & CONSTRUCTION

WATERWORKS / FIRE PROTECTION