Flow Control Principals and Hydraulic Flow Sensing...

Read More

BERMAD » Knowledge Center » Flow Control Valves

Flow Control Valves

What are flow control valves?

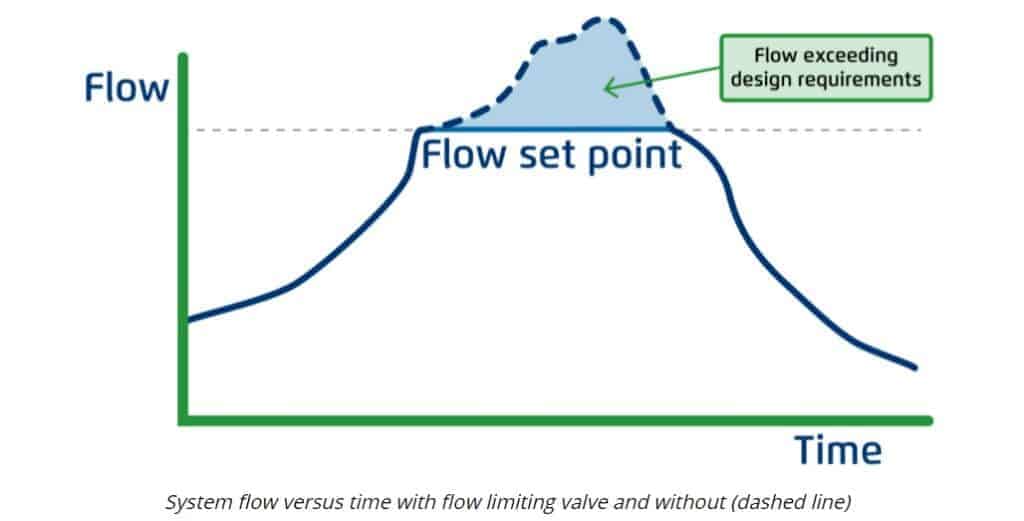

Flow control valves are designed to establish a constant pre-set maximum flow rate, regardless of fluctuating demand or varying system pressure, in order to prevent the supply system from over consumption (see below graphs).

There are different methods for applying flow control: mechanical, electronic and hydraulic. BERMAD offers fully automatic hydraulic flow control.

In irrigation for example, flow-limiting is required at the outlets from main systems to consumers such as mainline to hydrant line, hydrant line to distribution line and more.

In Waterworks flow control is required at reservoir inlets, mixing junctions etc.

Designers use flow control valves to ensure that the flow won’t exceed the system’s designed flow rate. Prioritizing it over users when they attempt to consume more than the system’s specifications.

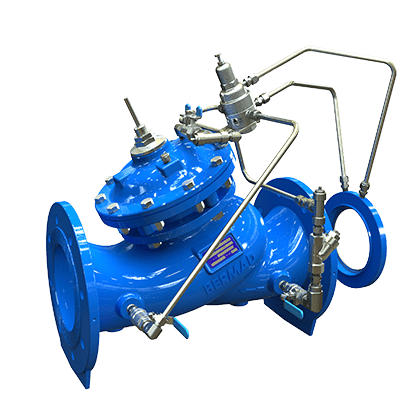

Flow Control Valve Operation at Low Pressures

The function of a flow control valve is to regulate flow at a constant rate – regardless of inlet water pressure. This can be especially challenging to accomplish at very low operating pressures within a network.

The Bermad Model 718 achieves this using its double chambered design.

Colin Kirkland, air valve product manager & technical training expert, Bermad Australia:

“One of the key reasons this valve is so successful in lower pressures, is the double chambered design of the valve’s main body. The double chamber has no internal spring – with two distinct control chambers remote from the water source.”

Colin mentions that this unique design is engineered for the following performance:

- Ability to operate with minimal head loss from pressures as low as 3m.

- Ability to modulate regardless of differential valve pressure.

- Ability to regulate in a linear manner without inducing water hammer during closure.

- Ability for the valve to have control solenoids fitted to the top, and if required, to lower chambers of the valves.

- Ability to immediately respond to a solenoid change, which reduces pulse lengths and power draw on the solenoids.

Flow Control Valve Diagram

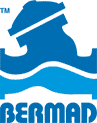

How do flow control valves work?

A Hydraulic Flow Control Valve is equipped with a flow control pilot designed to hydraulically sense the differential pressure associated with varying flows. The flow control pilot commands the valve to throttle when the demand increases above the setting and to open the valve when the demand decreases below the setting.

- Hydraulic flow control valves react to changes in the parameters they sense by either opening or closing to control the flow rate.

- This is a “progressive” process, meaning that an increase in demand results in the valve reducing the flow progressively.

- The more the valve closes, the more the downstream Flow rate is reduced.

- When demand is lower than design parameters, the valve opens.

What are the common types of Flow Control Valves?

System demand can vary due to different reasons, like unequal irrigation shifts in agriculture or typical municipal consumption in Waterworks.

In these cases, pilots must be designed to continuously measure the differential pressure.

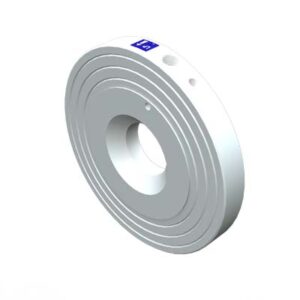

An example is using an Orifice Assy as a flow sensor and a differential pressure pilot to continuously senses the flowrate by changes in the differential pressure or ΔP across the orifice (connected by two sensing tubes).

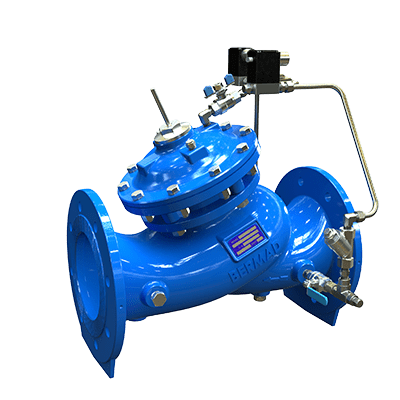

Refer to BERMAD flow control valve model 770-U product page.

For minimal headloss and easy in-filed recalibration BERMAD offers a unique paddle pilot sensor & a pilot dedicated for Irrigation system.

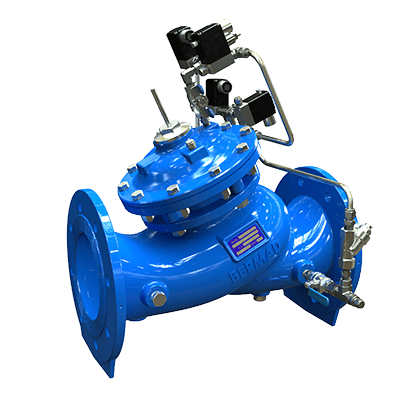

Refer to BERMAD flow control valve model 172-50-3W-Xt Product page.