AIR CONTROL IN WATER SYSTEMS

Read More

BERMAD » Knowledge Center » Knowledge Center Lobby

When to use air valves and what are their benefits and types?

What are the benefits and function of an air valve?

Control of air in water systems is as essential as control of water. The major benefits of using air valves are increased system efficiency and shorten filling time, saving of energy as well as protection from vacuum conditions and pipe collapse. The air valves control the air in each of the following stages:

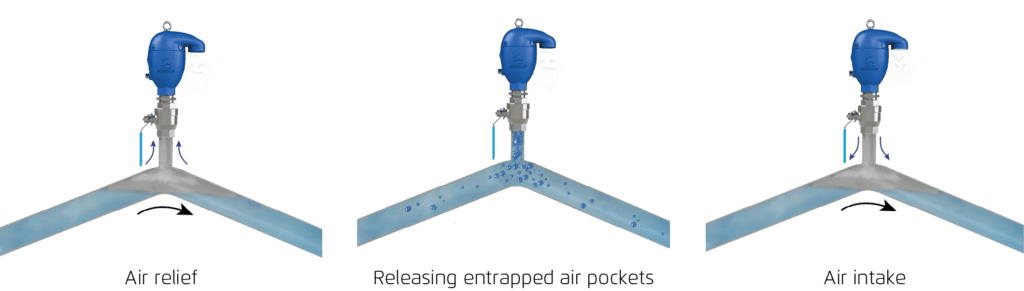

Pipeline filling

To allow efficient filling, air has to be relieved or evacuated. In case the air is not being effectively relieved, the pipeline filling time will increase significantly. A large volume of air, which was not relieved during pipeline filling, might lead to pressure surges.

Pressurized operation (Steady State)

Air bubbles will accumulate at the higher points in the system, and gradually reduce the effective cross section of the pipe. The result will be reduction in flow and increased energy costs (to maintain the design flow). In extreme cases, the pump will be unable to supply the required extra pressure needed to overcome the air pockets and flow in the system might completely stop.

In addition, air disturbs the operation components such as pumps, regulating valves and filters. Mechanical water meters, whose readings are based on liquid velocity, will provide inaccurate readings due to the presence of air in the meter. Also the presence of air in high volumes in the system will contribute to enhance corrosion in metal pipelines.

Pipeline draining

During system draining, whether due to burst or maintenance, negative pressures (Vacuum Conditions) will be created. Negative pressures may damage different components and under severe conditions can lead to pipeline collapse. Allowing air intake will eliminate negative pressures and protect the system.

Pressure surge (Water Hammer)

Pressure surges may be a result of pump trip, fast valve closure and more. It is likely, that in the same magnitude the pressure rises, it will also drop. In some cases, pressure becomes negative (Vacuum Conditions), and in worst cases water column separation may occur, along with cavity formation.

Without a proper control of the surge pressure, the system may suffer significant damages. Neutralizing the Vacuum Conditions will require air intake at critical points, based on Surge Analysis.

What are the types of an air valve?

There are 3 basic types of Air Valves:

1. Automatic Air Valve (Air Release)

The valve releases entrapped air pockets during pressurized operation. It has one single small orifice, called the Automatic Orifice, in diameters of 0.04 – 0.2 inch; 1 – 5 mm.

2. Kinetic Air valve (Air Relief/Intake)

The valve evacuates air during pipeline filling and enables air intake in the event of system draining or vacuum conditions. It has one single large orifice, called the Kinetic Orifice, in diameters of 1 – 10 inch; 25 – 250 mm. A Kinetic Air Valve, which is restricted only to air intake, is also known as Vacuum Breaker.

3. Combination Air Valve

The valve combines the function of Automatic and Kinetic Air Valves. It evacuates air during pipeline filling, allows efficient release of air pockets from pressurized pipes, and enables air intake in the event of network draining or

vacuum conditions. It has two orifices – Automatic and Kinetic.

Air Valves are also classified by the type of water:

1. Air valves for Clean Water:

To be used with drinking water, irrigation water, reused or recycled water.

2. Air valves for Non-Clean Water:

To be used with unclean waters, for example, municipal sewage, industrial and mining systems. Their function is the same as that of the Clean Water Air Valves; however, the main difference lies in their elongated body and internal parts designed to keep the water apart from the valve mechanism.

What are the additional features for Air Valves ?

1. Surge Protection – SP (Non-slam)

Designed for partially close the kinetic orifice during air relief. It prevents the slam/shock resulting from a rapid closure of the kinetic orifice during pipeline filling or water column separation. The Surge Protection feature ensures smoother operation and prevents damage to the air valve or system.

2. Assisted Closing – AC

This feature is similar to SP, but in this case the SP disc is held upwards using a spring. It means that, regardless of inline pressure, outflow is only through the SP disc (switching value = 0).

3. Inflow Prevention – IP

Prevents intake of atmospheric air in cases where this could lead to damaged pumps, required re-priming, or disruption of siphons. It also prevents intake of flood or polluted water into drinking water networks.

Download now the AIR CONTROL IN WATER SYSTEMS, A GUIDE FOR SYSTEM DESIGNERS

This guide offers tools for planning air control, selection and specifications of air valves