Pressure Reducing & Cavitation - Your Questions An...

Read More

BERMAD » Knowledge Center » Pressure Reducing Valves

Pressure Reducing Valves (PRV)

What Are Pressure Reducing Valves?

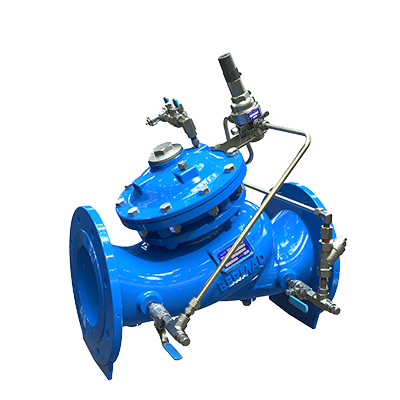

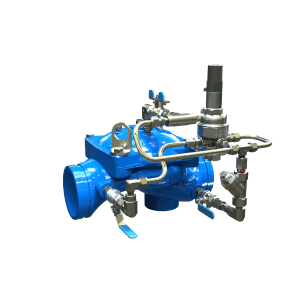

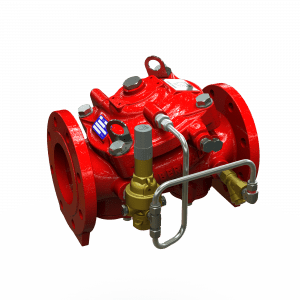

Hydraulically operated pressure reducing control valves reduce a higher upstream pressure to a constant lower downstream pressure, regardless of fluctuating demand or varying upstream pressure.

There are different methods for applying pressure reduction: mechanical, electronic and hydraulic.

BERMAD offers fully automatic hydraulic pressure reduction.

In municipal networks pressure reducing valves (PRV) are required at the inlet of pressure zones or DMAs (District Metering Areas). On the one hand, for protecting the equipment at the downstream and household plumbing from overpressure. On the other hand, guaranteeing sufficient & reliable pressure for the consumers.

In Irrigation PRVs are required in water headers in the entry of lower elevation fields, pivot-machines, low pressure systems like dripping pipes and more.

In high rise buildings, PRVs are located on every floor or every few floors, for protecting the department’s plumbing and low rated fittings & connections from overpressure.

How Do Pressure Reducing Valves Work?

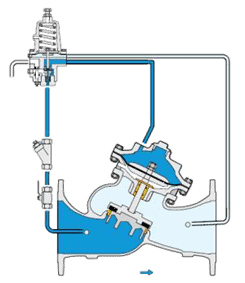

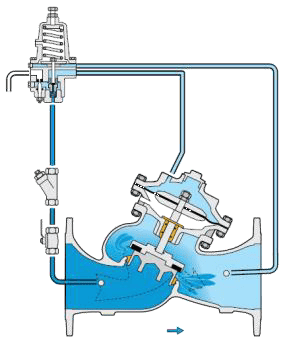

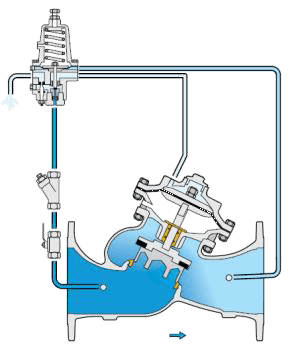

The hydraulic pressure reducing valves are equipped with a pressure reducing pilot designed to hydraulically sense the downstream pressure.

The pressure reducing pilot commands the valve to throttle/close when the downstream pressure increases ABOVE the pilot pressure set point and to open the valve when the downstream pressure decreases to BELOW the pilot pressure set point.

Example:

When downstream pressure is higher than the required set-point, the pilot allows water to flow from the upstream to the control chamber and the valve tends to close.

When downstream pressure is equal to the required set-point, the pilot keeps the water in the control chamber and the valve remains in the same position, not opening or closing, and thus retaining the set pressure.

When downstream pressure is lower than the required set-point, the pilot drains water from the control chamber to the atmosphere and the valve opens.

*This example refers to 3-way control method.

In Waterworks and Buildings 2-Way is common as well, which has somewhat different principles of operation.

What Are The Common Types of Pressure Reducing Valves?

System pressure can vary due to many different reasons. Pumps starting, changes in topography, pipe characteristics, the resistance of equipment along the system, leaks & water theft and of course the demand flow pattern which has a direct effect on the pressure loss across the pipeline.

In Waterworks & Buildings some systems supply water 24/7, and flow constantly vary throughout the day.

While in Irrigation & Fire Protection, flow is constant and occurs in shifts/pulses, depending on the crops or firefighting emergency events.

Based on this understanding there are many different types of Pressure Reducing Valves and configurations to optimally suit these varying requirements

Some rely on a 3-way control loop and others on 2-way. Some are full bore for minimal head loss during insufficient inlet pressure and others are reduced bore for achieving efficient pressure regulation.

Refer to pages: WW-720 or IR-120-X

Some have throttling devices to cope with low flows, and others have different mechanisms to eliminate/reduce cavitation.